Conveyor Gearmotor Lifting Beam

Client:

Large food processing plant

Location:

Beenleigh

Project description:

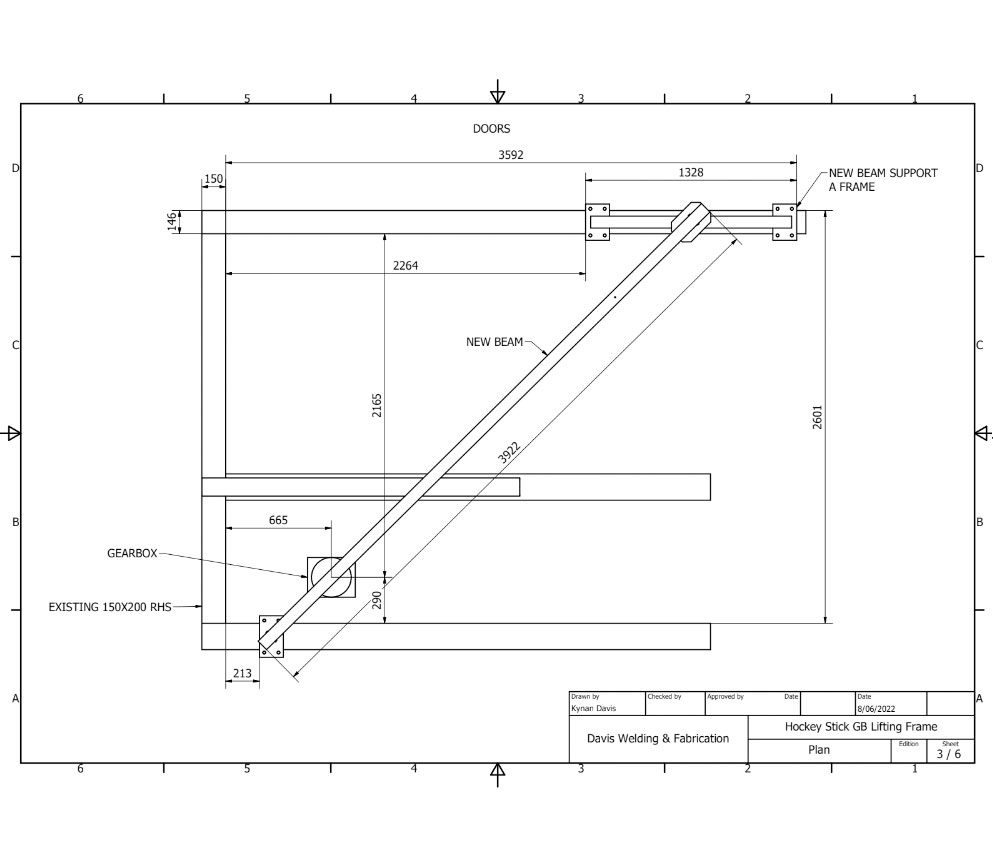

Design and fabrication of a conveyor gearmotor lifting beam for a food processing facility.

- A 300kg gearmotor needed to be replaced

- It was located 6m above the floor level

- It needed to be lowered down close to the building entrance

What were the challenges?

- The galvanized lifting beam had to be installed without the use of welding due to its location within a food processing facility.

- The gearmotor needed to be lifted from its location and wheeled along a beam to an area that was unobstructed below and then lowered to the ground.

- Safety was of paramount concern and access to the area below was restricted during construction for safety reasons.

How did Davis Welding and Fabrication solve these challenges?

- The positions of the surrounding beams were carefully measured as was the position of the gearmotor and the location where it could be lowered to the floor.

- A 3D model of the area was created. Using this model, a suitable monorail lifting beam was designed which clamped on to the existing surrounding structure.

- Scaffold was used to get access to install the monorail.

- The new monorail was certified by an engineer to ensure compliance and safety regulations were met.

Project result

- The newly fabricated and installed metal monorail allowed the gearmotor to be replaced easily and safely.

Category:

Date:

January 5, 2023