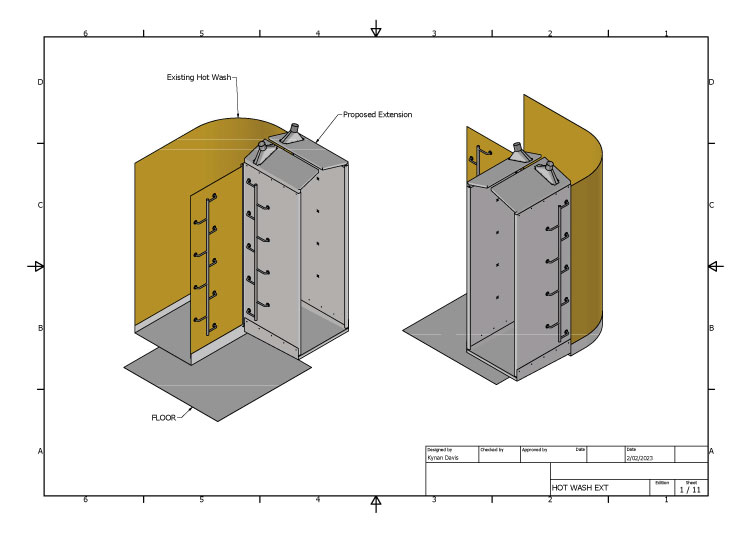

Spray Cabinet Fabrication

Client

Large Food Processing Plant, Brisbane

Project description:

Design, fabrication and installation of an extension to an existing spray cabinet

What were the challenges?

The large size of the spray cabinet meant that it needed to be manufactured as a bolt together unit. 9 sprays were needed on each side of the cabinet.

How did Davis Welding and Fabrication solve these challenges?

- A weekend site visit was planned to gather the necessary measurements of the cabinet extension.

- A preliminary design was drawn up and sent to the client for further input.

- The design involved the cabinet being constructed from folded panels that bolted together onsite.

- A manifold on each side of the cabinet supplies the 18 sprays with water.

- Each panel was laser cut ensuring accurate placement of all bolt holes and spray locations.

Project result

- The cabinet and spray bars were assembled piece by piece and completed in one day.

- We then measured up the plumbing required to connect the spray bars and installed it on the following weekend.

Category:

Date:

June 14, 2023